The Complete Guide to Creating a Factory-Ready Tech Pack (For Clothing Production)

If you want your clothing designs to be produced exactly as you imagine them, you must learn how to create a tech pack that factories can clearly understand. A factory-ready tech pack for clothing is the foundation of professional apparel production. Without it, production relies on guesswork, which leads to mistakes, delays, and rejected samples.

Without a clear tech pack, brands commonly face:

- Incorrect garment construction

- Wrong fabric selection

- Poor fit

- Extra sampling costs

- Production delays

A tech pack removes uncertainty by converting your design into technical instructions.

In This Guide, You Will Learn:

- What a tech pack is

You will understand what a tech pack contains and how it functions as a technical instruction file for garment production. - Why factories reject unclear ones

You will learn the technical and operational reasons factories refuse poorly prepared tech packs. - A step-by-step breakdown of tech pack pages

You will see how each page of a professional tech pack is structured and what information must be included. - Real production mistakes brands make

You will study common real-world errors caused by missing or vague specifications. - A downloadable checklist to avoid errors

You will get a structured checklist to verify your tech pack before sending it to a factory

What Is a Tech Pack?

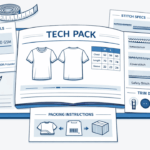

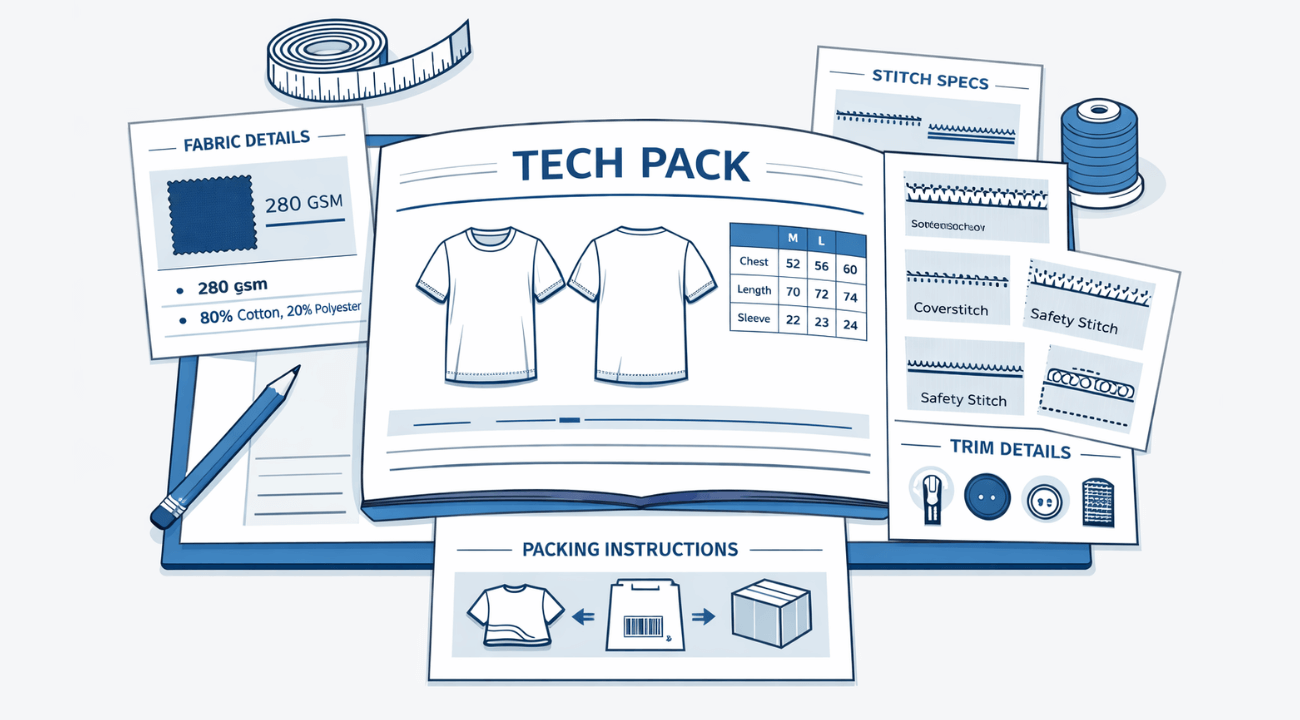

A tech pack for clothing is a standardized technical specification file that defines:

What the garment looks like

This includes technical drawings that show the exact shape, silhouette, and design details of the garment, such as neckline style, sleeve type, pocket placement, and seam lines. It visually communicates the design in a way the factory can interpret without guessing.

What materials it uses

This specifies the fabrics and trims required to make the garment, including fabric type, composition, weight (GSM), and any additional components like zippers, buttons, ribbing, or drawstrings. It ensures the factory sources and uses the correct materials.

How it is constructed

This explains how the garment pieces are assembled, including stitch types, seam methods, and construction order. It tells the factory which machines and sewing techniques must be used to achieve the desired durability and finish.

What size it must be

This defines the garment’s measurements through a size chart with points of measurement and tolerance levels. It ensures consistency in fit across all sizes and prevents random scaling during production.

How it must be packed

This outlines how the finished garment should be folded, bagged, labeled, and boxed for shipping. It ensures the product arrives in uniform condition and meets your brand’s logistics and presentation standards.

It serves three critical functions:

It translates design ideas into technical data, provides precise manufacturing instructions, and acts as a reference for quality control and production approval.

1. Design Translation

A tech pack transforms your creative garment idea into technical information that a factory can understand and reproduce accurately.

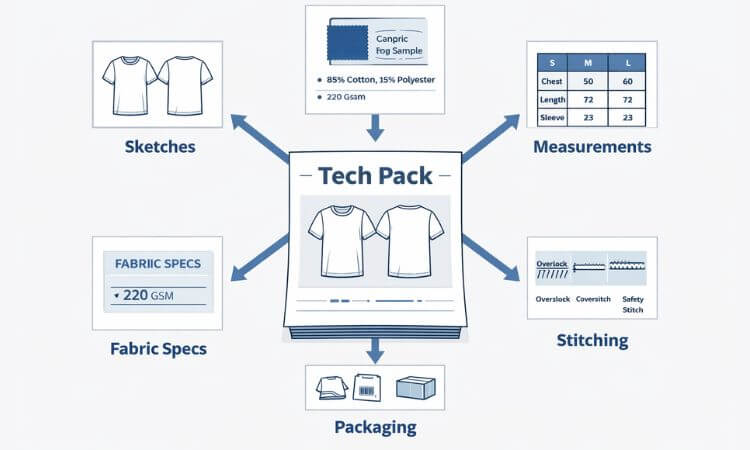

Visual design → technical sketch

Your fashion idea is converted into precise flat drawings that show the exact shape, panels, seams, and details of the garment, removing artistic interpretation.

Style concept → stitch type

Your design intention (for example, casual, durable, or premium) is translated into specific stitch types and construction methods that achieve the required look and strength.

Fit idea → numerical measurements

Your idea of how the garment should fit (oversized, slim, relaxed) is converted into exact measurements and size charts so the fit can be consistently produced.

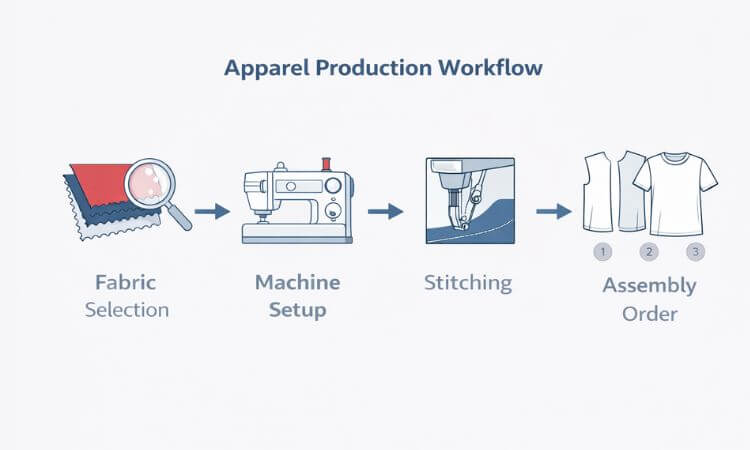

2. Manufacturing Instruction

A tech pack acts as a step-by-step technical guide for the factory during production.

Which fabric to use

It specifies the exact fabric type, composition, and weight so the factory does not substitute materials or guess quality.

Which machines to use

It indicates the required sewing and finishing machines based on the construction and stitch types, helping the factory set up the correct production line.

Which stitch types to apply

It defines the exact stitches for each garment part to ensure durability, appearance, and consistency across all pieces.

Which sequence to sew in

It outlines the correct order of assembly so the garment is constructed properly and efficiently without structural errors.

3. Legal & Quality Reference

A tech pack becomes the official technical standard used to judge whether production is correct or incorrect.

Sample approval

The first sample is compared directly to the tech pack to confirm that the design, size, and construction match the documented specifications.

Bulk production

Once approved, the same tech pack is used as the blueprint for mass manufacturing to maintain uniformity across all units.

Quality inspection

Inspectors use the tech pack as a checklist to verify measurements, fabric quality, stitching, and branding placement before shipment.

Dispute resolution

If problems occur, the tech pack is used to determine responsibility by checking whether the requirement was clearly specified.

If a defect appears, the factory will ask:

“Is this mentioned in the tech pack?”

If it is mentioned and not followed, the factory is responsible.

If it is not mentioned, the responsibility falls on the brand for not defining the requirement.

“A tech pack for clothing is a detailed technical instruction document sent to manufacturers. It defines exactly how a garment should be produced, leaving no room for interpretation.

It acts as a blueprint for garment production, similar to how architectural plans guide the construction of a building.”

2. Why Factories Reject Unclear Tech Packs

Factories reject tech packs because unclear specifications increase production risk and reduce efficiency.

They increase financial risk

When instructions are missing or vague, the factory may produce incorrect samples or bulk goods that cannot be sold. This leads to material waste, rework, and financial loss for both the factory and the brand.

They slow down production

Unclear tech packs force factories to ask repeated questions, stop the production line, and wait for clarifications. This delays sampling, approvals, and bulk manufacturing schedules.

They cause quality inconsistency

Without fixed standards, different workers interpret instructions differently. This results in variations in size, stitching, and finish across garments, making quality control difficult.

Main Technical Reasons

2.1 No Defined Measurement Logic

Factories measure garments using Points of Measurement (POM), which are standardized locations where dimensions are taken. If POM is not defined, each person may measure from a different spot, creating inconsistent results.

Wrong:

Chest = 56 cm

Correct:

Chest width measured 2.5 cm below armhole seam = 56 cm ± 1 cm

Without defined POM:

- One operator measures from a different point

- Quality control cannot verify accuracy

- Fit varies from piece to piece and becomes unpredictable

2.2 Fabric Defined in Marketing Language

Factories do not work with descriptive or emotional terms such as:

- “Premium cotton”

- “Soft feel”

- “Luxury fabric”

These words have no technical meaning in textile production. Instead, factories require measurable textile data so they can source and match the correct material.

They need:

- Whether the fabric is knit or woven

- Fabric weight (GSM)

- Fiber composition

- Yarn type

- Shrinkage percentage

Correct example:

Single jersey knit, 100% combed cotton, 220 GSM, enzyme washed, shrinkage below 5%

This allows the factory to source fabric that behaves correctly in production and after washing.

2.3 Stitch Type Not Specified

Every stitch type differs in:

- Cost

- Strength

- Machine requirement

- Appearance

If stitch type is not specified, the factory will usually choose the fastest and cheapest option to meet deadlines and cost targets.

Wrong:

Sew panels together

Correct:

Side seams: 4-thread overlock

Shoulder seams: safety stitch

Hem: 2 cm coverstitch

Specifying stitch types ensures durability, visual consistency, and controlled production quality.

2.4 No Construction Sequence

Garments are assembled in a logical order, such as:

- Joining shoulders

- Attaching sleeves

- Closing side seams

- Finishing hems

If this construction logic is unclear or not illustrated, workers may assemble parts in the wrong order, leading to twisted seams, incorrect alignment, or poor fit. Clear construction flow prevents structural mistakes during sewing.

2.5 No Branding Position Defined

Branding placement must be defined using measurable reference points, not general descriptions.

Wrong:

Place logo on chest

Correct:

Screen print logo 8 cm below neckline seam, centered horizontally, width 6 cm

Factories need distances from seams and alignment references, not visual guesswork. Without this, logos may appear too high, too low, or off-center, damaging brand presentation.

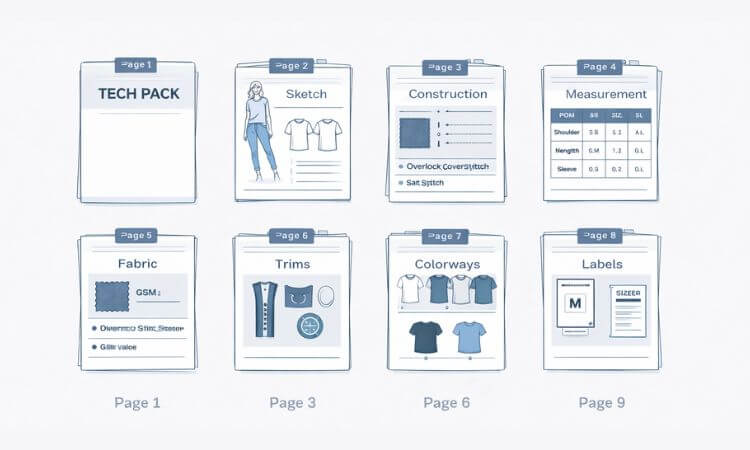

3. Step-by-Step Breakdown of a Factory-Ready Tech Pack

A factory-ready tech pack is organized into separate technical pages so that each department in the factory (pattern, cutting, sewing, and packing) can easily find the information they need. Each page has a specific role in guiding production and preventing errors.

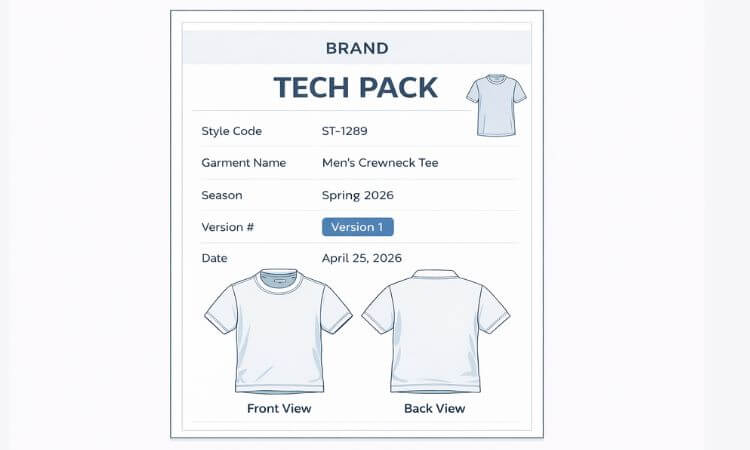

PAGE 1: Cover Page (Style Identification)

Purpose: Prevent confusion inside factory systems.

Factories handle many styles at the same time. The cover page ensures your garment is correctly identified and tracked throughout sampling and production.

Must include:

- Brand name

- Style code

- Garment name

- Collection or season

- Version number

- Date

- Designer or merchandiser contact

Why versioning matters:

Every time you change a detail (for example, sleeve length or fabric), the version number must be updated. If the version is not changed, the factory may continue using an older file and produce garments based on outdated instructions.

Example:

Style Code: SZ-TS-101

Garment: Oversized T-Shirt

Season: Summer 2026

Version: V3

PAGE 2: Technical Flat Sketches

These are construction drawings, not fashion artwork. Their purpose is to visually explain how the garment is built.

Must show:

- Front view

- Back view

- Close-ups of key areas such as:

- Neck

- Cuff

- Hood

- Placket

They must include:

- Stitch lines

- Panel separation

- Rib areas

- Seam locations

Purpose:

These sketches allow the pattern maker to understand the garment structure and create accurate pattern pieces without guessing design details.

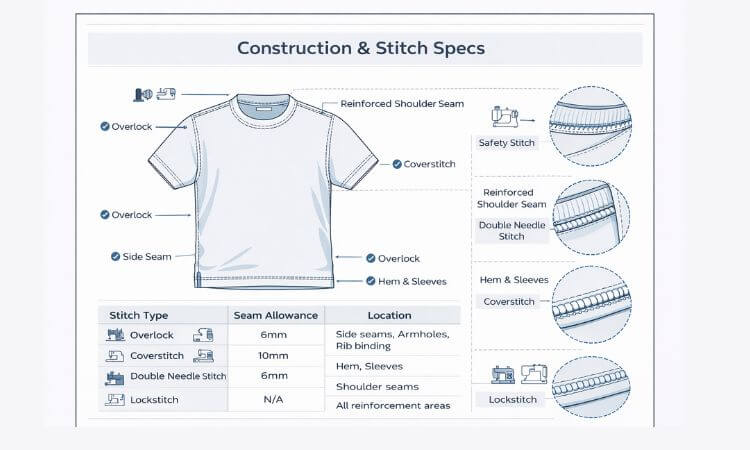

PAGE 3: Construction & Stitch Specification

This page explains how the garment pieces are joined together.

- Must specify:

- Stitch type

- Stitch density

- Seam allowance

- Reinforcement points (such as bar tacks or stress areas)

Example:

Area Stitch Seam Allowance

Shoulder Safety stitch 1 cm

Neck rib Twin needle 0.8 cm

Pocket edge Bar tack N/A

Bottom hem Coverstitch 2 cm

This prevents:

- Seam tearing due to weak construction

- Factories choosing cheaper stitching methods

- Inconsistent stitching quality across garments

PAGE 4: Measurement Specification (Size Chart)

This page defines the fit of the garment.

Include:

- Base size (usually M or L)

- POM (Points of Measurement) diagram

- Tolerance (allowed variation)

- Grading increments for other sizes

Example:

POM M L XL Tol

Chest 56 59 62 ±1

Length 72 74 76 ±1

Sleeve 62 64 66 ±1

Add a diagram with arrows showing exactly where each measurement must be taken.

Without a diagram:

Different workers may measure from different points, which leads to inconsistent sizing and unreliable fit.

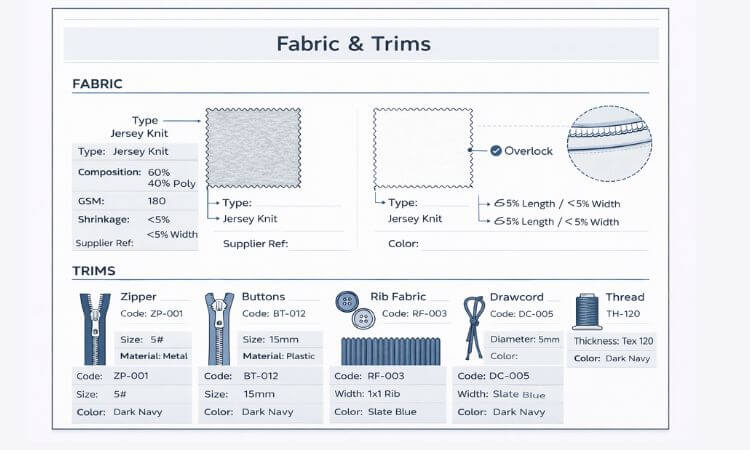

PAGE 5: Fabric Specification

This page defines how the material should behave during sewing and after washing.

Must include:

- Fabric type

- Whether it is knit or woven

- GSM (fabric weight)

- Fiber content

- Finish (enzyme wash, brushed, etc.)

- Shrinkage

- Color

Example:

Fabric: French terry knit

Composition: 80% cotton / 20% polyester

GSM: 280

Shrinkage: <5%

This affects:

- Weight of the garment

- Cost of production

- How the garment drapes on the body

- Durability after repeated washing

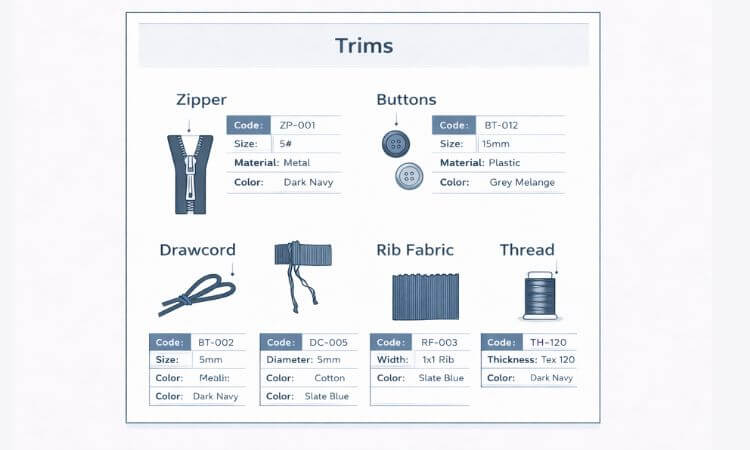

PAGE 6: Trim Specification

This page defines all non-fabric components used in the garment.

Include:

- Zipper length and type

- Button material

- Drawcord thickness

- Rib fabric composition

- Thread color

Example:

Zipper: Nylon coil 5 mm, black, YKK equivalent

Drawcord: 6 mm cotton rope

Rib: 2×2 rib, 95% cotton, 5% elastane

This ensures that small components match your design and quality level instead of being substituted with cheaper alternatives.

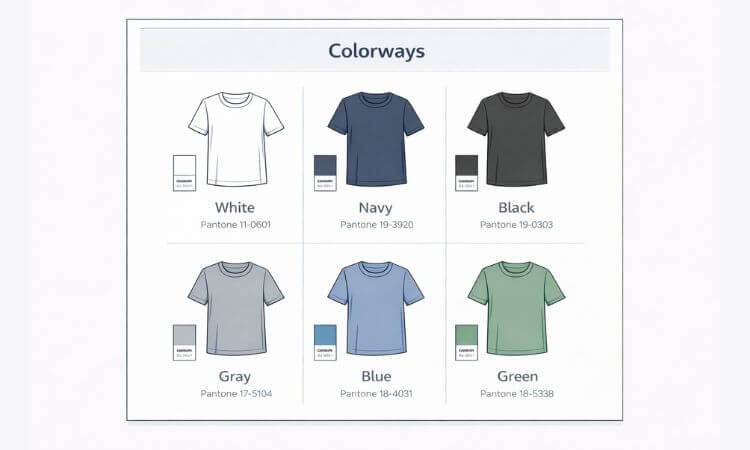

PAGE 7: Colorways

This page defines the exact colors used on each part of the garment.

Include:

- Body color

- Rib color

- Stitch color

- Print or embroidery color

Use standardized color references such as Pantone to avoid shade variation.

Example:

Body: Pantone Black C

Rib: Pantone Cool Gray 11 C

Stitch: Pantone Black C

This ensures color consistency across different production batches.

PAGE 8: Label & Branding Placement

This page defines how and where branding elements are applied.

Include:

- Main label size

- Care label text

- Hang tag placement

- Logo position

- Provide a diagram showing:

- Distance from seam

- Center alignment

- Size in centimeters

This prevents logos and labels from being placed too high, too low, or off-center.

PAGE 9: Packaging & Folding

This page defines how the finished garment must be prepared for shipping.

Include:

- Fold method

- Polybag size

- Barcode position

- Units per carton

Example:

Fold: Vertical 3-fold

Polybag: 30 × 40 cm

Carton: 50 pcs

Clear packaging instructions ensure that garments arrive in uniform condition and meet warehouse and retail requirements.

4. Real Production Mistakes (Industry Reality)

These are common mistakes seen in real garment production when tech packs are incomplete or unclear.

Mistake 1: No Shrinkage Mentioned

Result: Garments shrink after wash.

If fabric shrinkage is not specified, the factory produces garments at the exact given measurements. After washing, the fabric shrinks and the garment becomes smaller than the intended size, leading to customer complaints and high return rates.

Mistake 2: No Tolerance

Result: QC rejects large quantities.

Without tolerance limits (for example, ±1 cm), quality control has no acceptable range to judge measurements. Even small variations cause garments to fail inspection, resulting in high rejection rates and wasted production.

Mistake 3: No Stitch Defined

Result: Weak seams.

When stitch types are not specified, the factory may use the cheapest and fastest stitch. This often leads to weak seams that break after limited use or washing, reducing product durability and brand trust.

Mistake 4: No Label Diagram

Result: Misaligned branding.

If label or logo placement is described only in words and not shown with measurements and diagrams, factories may place branding too high, too low, or off-center. This damages the professional appearance of the garment.

Mistake 5: No Version Control

Result: Factory follows old file.

When updated changes are made without changing the version number, the factory may continue using an older tech pack. This causes garments to be produced with outdated measurements or construction details.

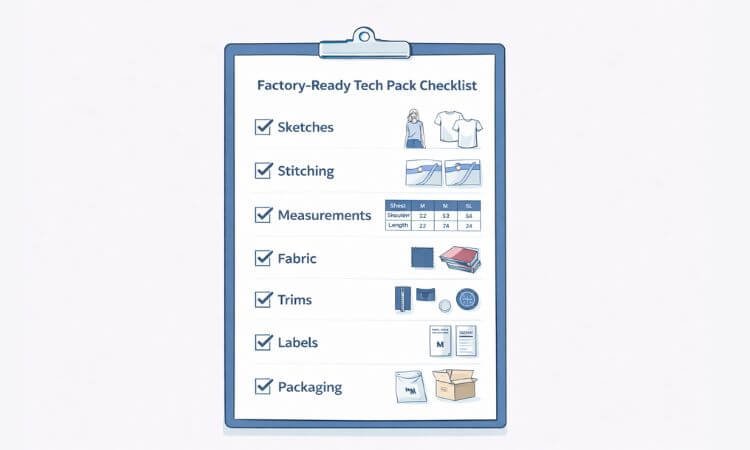

5. Downloadable Factory-Ready Tech Pack Checklist

Before sending your tech pack to a factory, it should be checked against a standard list to ensure nothing critical is missing.

✓ Technical flat sketches – to clearly show garment structure

✓ Stitch types defined – to control strength and appearance

✓ Seam allowances – to ensure correct assembly

✓ Fabric GSM & composition – to guarantee material quality

✓ Trim details – to avoid wrong zippers, buttons, or cords

✓ Measurement chart with tolerance – to control fit accuracy

✓ Grading rules – to scale sizes correctly

✓ Colorways with Pantone – to maintain color consistency

✓ Label placement diagram – to control branding position

✓ Packaging instructions – to standardize folding and shipping

✓ Version number – to prevent use of outdated files

✓ Contact info – so the factory can clarify doubts quickly

This checklist can be used as a printable reference or converted into a downloadable worksheet for teams and students.

Final Conclusion

Factories do not fail brands.

Unclear tech packs fail brands.

A factory-ready tech pack for clothing:

- Removes assumptions from production

- Controls manufacturing costs

- Sets clear quality standards

- Reduces repeated sampling

- Improves long-term scalability

Learning how to create a tech pack is a core professional skill in fashion production. It transforms creative ideas into repeatable, manufacturable products.

A design without a tech pack is only an idea.

A design with a tech pack becomes a product.